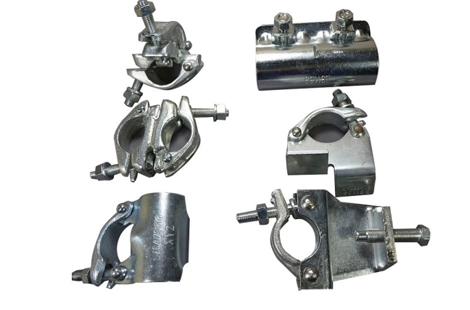

The coupler scaffolding system is suitable for the design and construction of formwork support in industrial and civil building concrete structures. Coupler scaffolding systems can also be referenced for use in the construction of grid frames, steel structures, and inclined concrete beam and slab formwork, considering the impact of horizontal loads.

The coupler scaffolding system has a large load-bearing capacity, is easy to dismantle, offers flexibility in setup, is simple to process, and has a low initial investment cost, making it an economical option. Due to its stable structure and ease of installation, the coupler scaffolding system has become the preferred choice for formwork support in construction.

Foundation treatment → Measurement and layout → Laying of base timber and installation of bases → Placement of longitudinal and horizontal sweep rods → Scaffold setup → Connecting and reinforcing the scaffold frame → Laying of the top board → Quality inspection → Rebar tying → Concealed inspection → Concrete pouring → Formwork removal → Construction of the next level.

Formwork should be processed in a centralized location using precision saw machines. Formwork processing at the construction site or on the construction level is strictly prohibited.

The formwork should be lined and drilled in the centralized processing area, and each piece of formwork should be marked to indicate its front and back. After processing, the formwork should be neatly stacked and marked with dimensions.

Control lines for formwork should be established, and the supervisor must review the position according to the control lines before installing the floor's steel reinforcement.

The control line for wall and column formwork on each floor should be determined according to the drawings, with a distance of 200–300mm from the wall or column.

Base blocks should be set at the bottom of the scaffold vertical rods, and these base blocks should not be smaller than 200×100×50 wooden blocks (length×width×height) or 50 scaffold boards, arranged in the same direction.

After fabricating the wall and column side formwork according to the drawing dimensions, mark the position lines for the columns and install the wall and column formwork after fixing the base boards. Two vertical directions should be added for diagonal bracing. When installing external formwork for shear walls, reserve old threaded rods and attach sponge pads to prevent misalignment and slurry leakage at the joint between floors. To prevent damage to the root of internal walls, mortar should be used to seal the exterior side at the bottom of the formwork.

Before installing the bottom formwork of beams, install the column head formwork first. The bottom formwork should be leveled using a string line. When the beam span is ≥4m, arching should be done as per regulations, and the arch height should be 1/1000 to 3/1000 of the beam span. The sequence of arching is as follows: arch the main beam first, then the secondary beams. When the beam height exceeds 600mm, the beam side formwork must be reinforced using pull rods. Separate vertical rods must be set under the beam and connected to the support frame, with no less than two connection points. The formwork system for edge beams must not be connected to the outer scaffold.

Wall and column formwork should be removed only after the concrete strength reaches 1.2MPa (without mold adhesion or corner loss, usually after reaching 1.2MPa).

The removal of the bottom formwork should only occur once the concrete strength reaches the required level for formwork removal, and after approval by the project's chief engineer and supervisor.

For post-casting joints, independent supports should be used, separated from the main structure's scaffold. Support should be retained until the post-casting joint has reached 100% strength before removal.

The coupler scaffolding system is an ideal choice for formwork support construction due to its stable structure, ease of installation, and strong load-bearing capacity. To ensure safety and efficiency in construction, selecting high-quality coupler scaffolding systems is critical. As a professional construction equipment supplier, Taishenglan offers high-standard coupler scaffolding systems to ensure the safety and efficiency of your projects.